High Density Polyethylene (PE100-RC)

High Density Polyethylene was first developed in 1953, at the Kaiser Wilhelm Institute in Germany. Since then, significant developments have been made to enhance material strength & chemical resistance. Polyethylene is currently the most abundant plastic in terms of production and has a multitude of uses. Chem Resist use PE100-RC, which boasts the following properties;

- Excellent resistance to a wide range of chemical applications, on all surfaces, internal and external

- A specified design life with unlimited fill and empty cycles

- Highly ductile, flexible and lightweight

- pH resistance across the full range

- Extremely low coefficient of thermal conductivity

- Suitable for outdoor use due to its UV stability

- Maintained integrity at very low temperatures

- Compliant with EU Directive 2002/72/EU (Food grade Plastic Materials) and WRAS approve

Material Specification

High Density Polyethylene PE-100

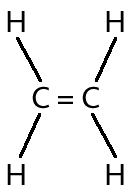

Polyethylene is manufactured by the low pressure polymerisation of ethylene. The structure of ethylene is given in figure 1.

Polyethylene molecules are branched, with the degree of branching in the molecular chains and the length of side chains having a considerable effect on the properties of polyethylene. When molten polyethylene cools, it crystallises. Different degrees of crystallisation produce different densities, due to the crystallisation regions having a higher density than amorphous regions. The degree of crystallinity ranges between 35% and 80% according to polyethylene grade. High density polyethylene (HDPE) attains a 60-80% degree of crystallinity at a density of 0.940 g/cm3 to 0.965 g/cm3; medium density polyethylene (MDPE) attains a 50-60% degree of crystallinity at a density of 0.930 g/cm3.

The properties of polyethylene are primarily determined by density, molar mass and molar mass distribution.

With increasing density (higher crystallinity), the following properties are increased: tensile strength; stiffness; hardness; solvent resistance, while the permeability to gases and vapours is reduced. On the other hand impact strength, transparency and stress cracking resistance decrease with increasing density.

The cylinders of Chem Resist vessels are extrusion wound in virgin High Density Polyethylene PE100.

This Black material exhibits excellent corrosion resistance to a wide range of inorganic and organic acids and bases. PE100 complies with EU Directive 2002/72/EU (Food grade Plastic Materials) and is WRAS approved (Certificate 1105531).

| Properties of High Density Polyethylene | |||

| Property | Test Method | Units | Value |

| Nominal Density | DIN 53479 | g/cm3 | 0.96 |

| Breaking Strength | DIN 53455 | N/mm2 | 37 |

| E-Modulus through bending (60s – value) | DIN 53457 | N/mm2 | 1000 |

| Impact Strength | DIN 53453 | kJ/m2 | 83 |

| Hardness | DIN 53505 | Shore D | 61 |

| Linear Coefficient of Thermal Expansion | ASTM D696-44 | 1/K | 2.0 x 10-4 |

| Thermal Conductivity | DIN 52612 | W/m K | 0.40 |

| Working Temperature without Mechanical Pressure | DIN 53446 | ºC | -40 TO +80 |

Read this PDF for more details